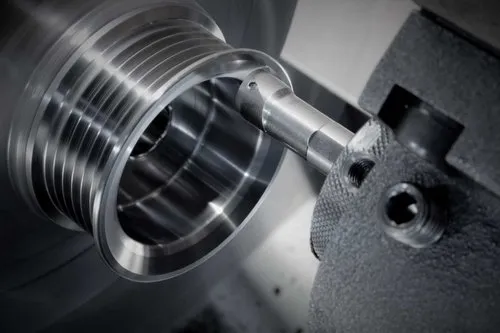

7 Ways To Repair CNC Machine Tools

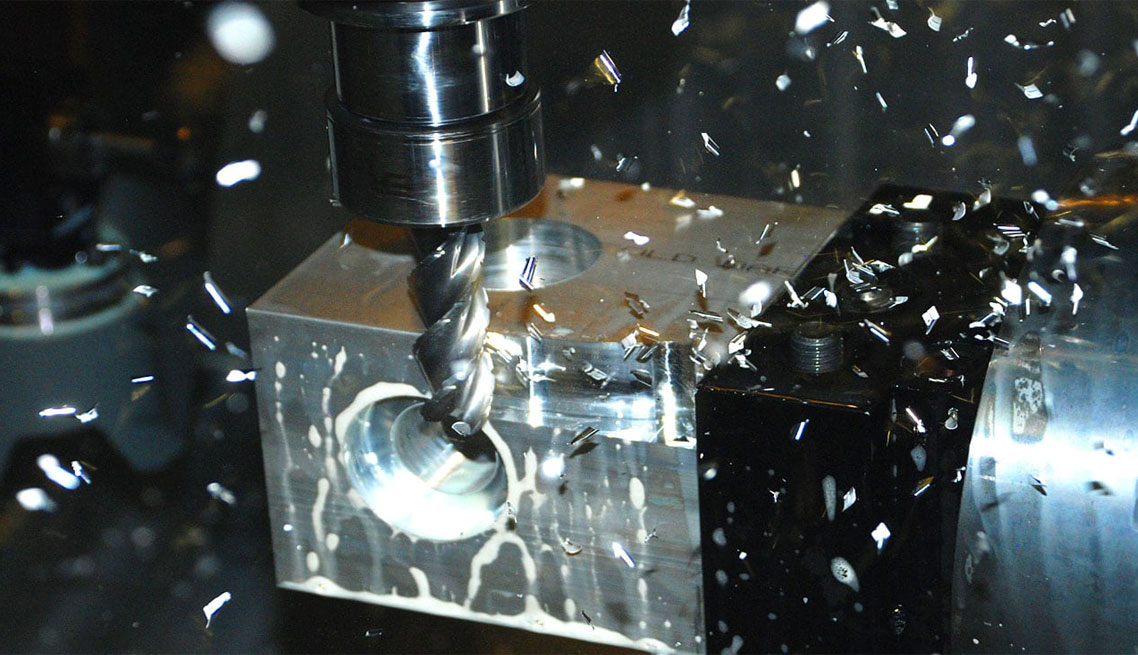

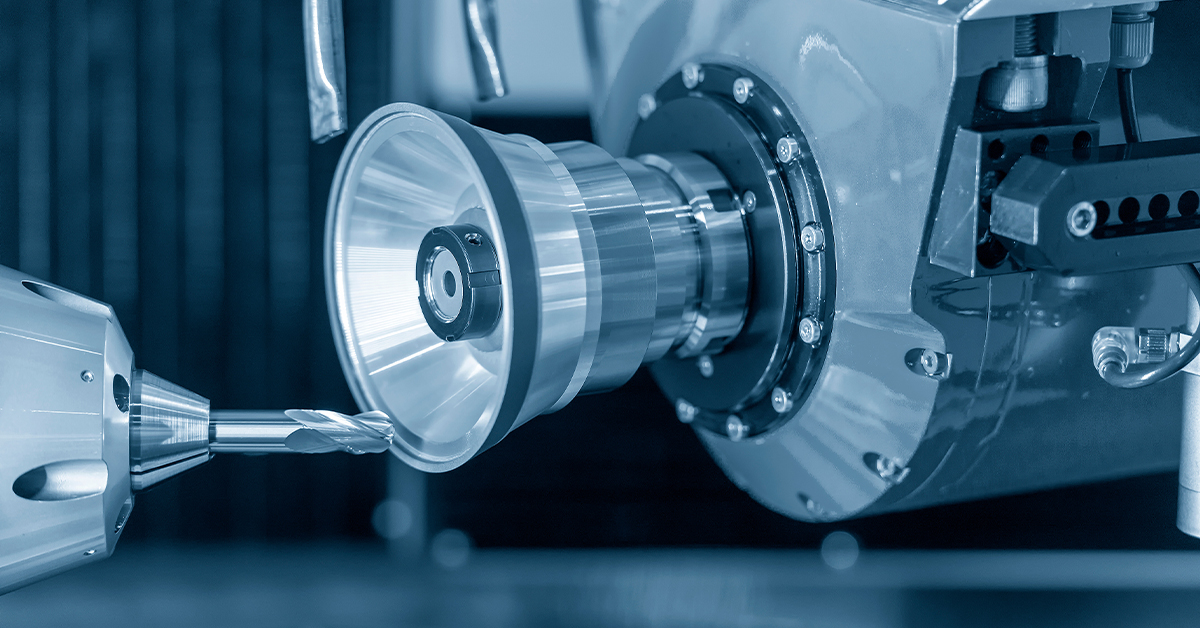

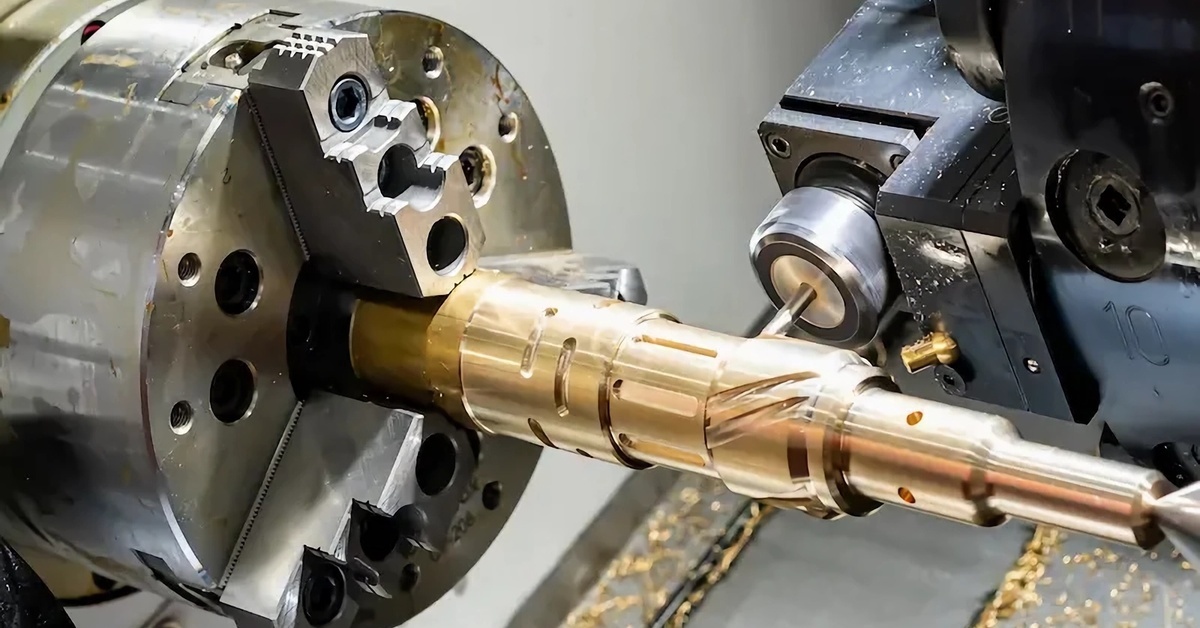

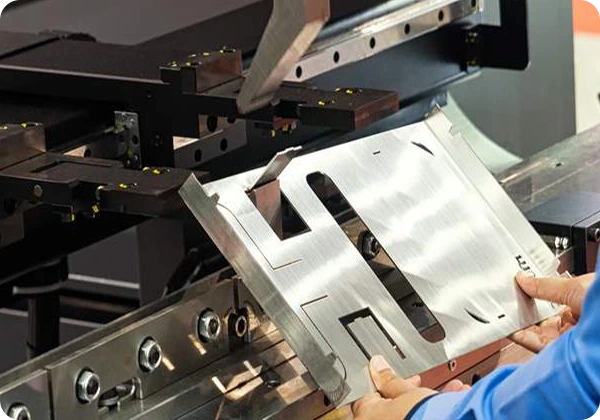

Methods to repair CNC machine tools include calibration, lubrication, replacing worn parts, updating software, diagnosing electrical issues, and ensuring proper alignment. Check hydraulic pressure When maintaining CNC machine tools, it is essential to carefully monitor the hydraulic pressure. Hydraulics are used for all the critical functions operated at such machines, such as tool change and …