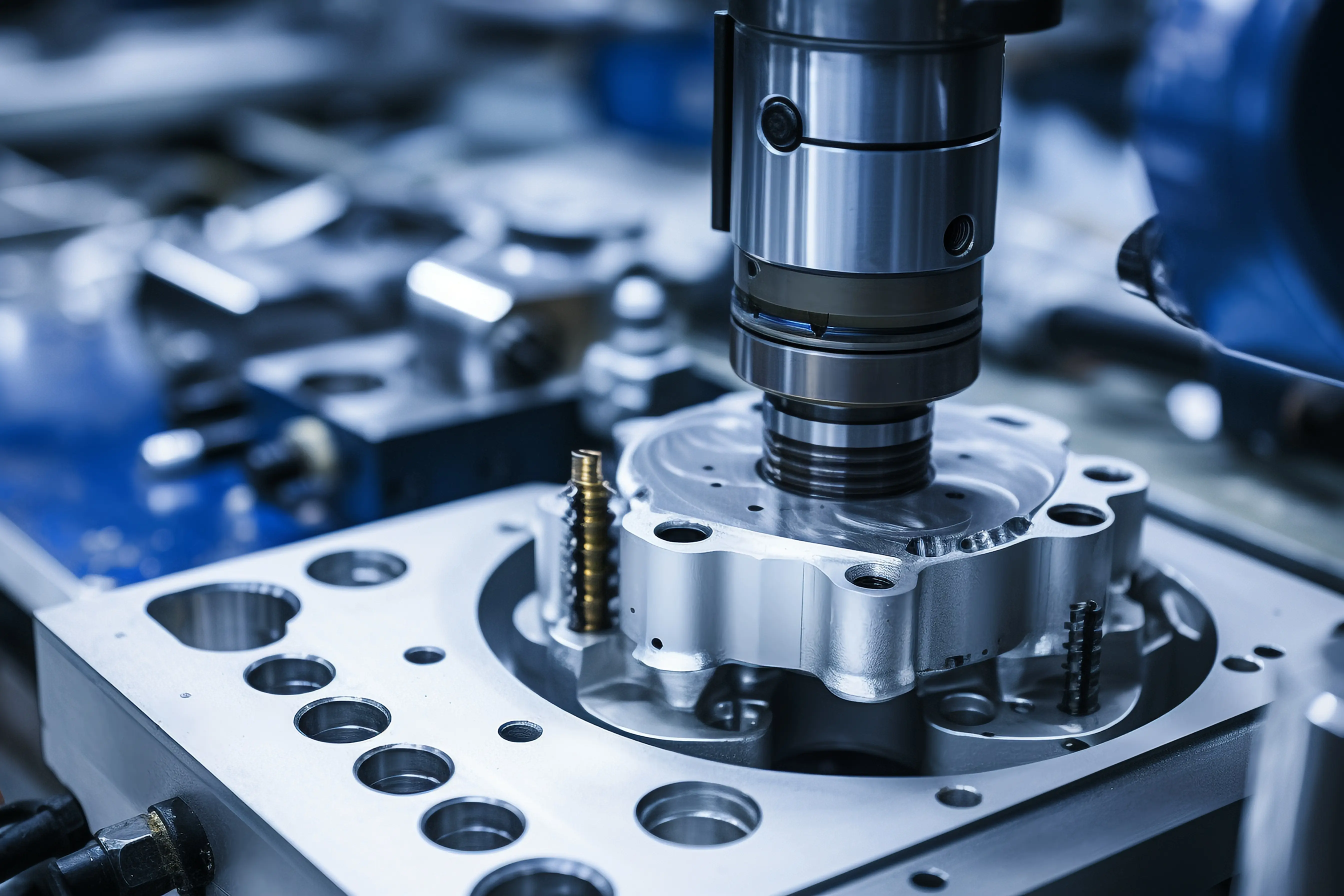

CNC Machining Services

Precision, Expertise, and Reliability in Every Component

Discover precision and quality with RS MFG’s CNC machining services. Our advanced facility and expert team efficiently handle complex projects, from prototyping to full-scale production

Why Choose RS MFG for CNC Machining?

Our diverse array of CNC machines ensures we meet the unique demands of each project.

We're skilled in working with a wide range of materials, ensuring versatility in our services.

We meticulously tailor our services, ensuring a seamless alignment with your unique project requirements.

We match lower prices for comparable qualityand service.

Our proactive and responsive team ensures your needs are met promptly and effectively.

Our CNC Machining Capabilities

CNC Milling Machines

ur 3, 4, and 5-axis milling machines deliver unparalleled precision, turning intricate designs into perfectly crafted components.

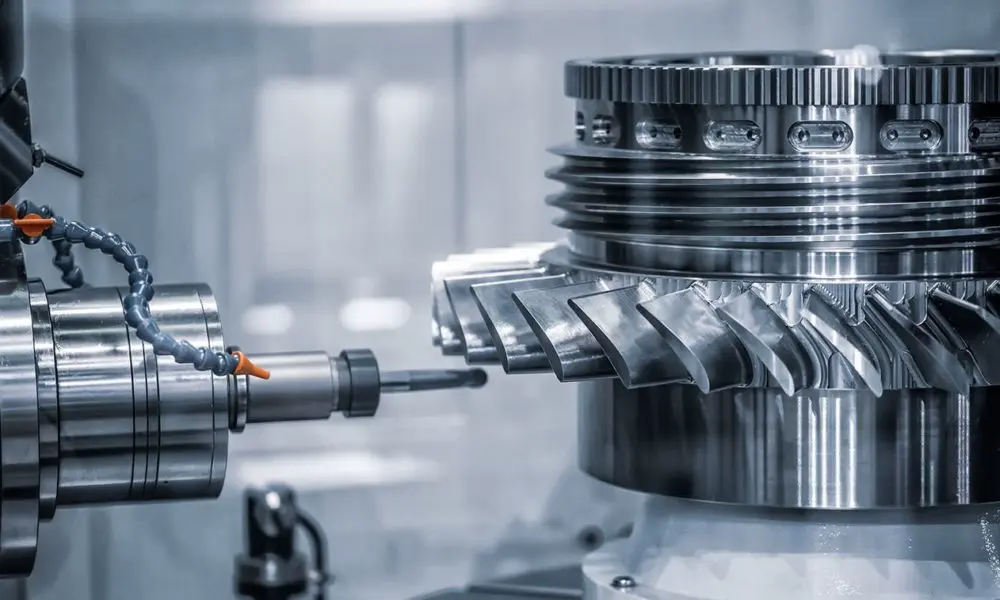

CNC Turning Centers

Expertise meets efficiency in our 2 and multi-axis lathes, ensuring high precision and streamlined production for every project.

CNC Drilling Machines

Advanced drilling machines provide speed and accuracy, ensuring quick, precise production and perfectly placed holes every time.

CNC Grinding Machines

Our precision grinders guarantee smooth, accurate finishes, ensuring each component meets the highest standards of perfection.

Specialized CNC Equipment

Offering specialized solutions with EDM, Waterjet, Laser, and Plasma cutting, we meet unique project needs with precision and innovation.

Supporting Equipment

Comprehensive inspection, finishing, and material handling equipment ensure quality and efficiency from start to finish in every project.

Industries We Serve & Case Study

Faced with a complex component for a new suspension system, we partnered with a leading automotive manufacturer. Our tailored CNC milling and rigorous quality control ensured the precision and performance of the part, maintaining the client's production line efficiency and leading to a long-term partnership.

Collaborating with a top aerospace company, we tackled the manufacture of critical jet engine components from high-grade alloys. Our precise CNC milling and turning, combined with stringent quality assurance, ensured the components exceeded performance and durability expectations, contributing to the engine's overall efficiency and reliability.

A medical device startup approached us to create components for a revolutionary device. We provided expert guidance on material selection and used our precision CNC machining to produce prototypes that met strict medical standards. Our meticulous attention to detail and rigorous quality checks were pivotal in advancing the device to the final stages of development and regulatory approval.

Ready to Get a CNC Machining Quote?

Ready to get a CNC Machining quote? We’re excited to work with you to provide top-quality custom services. Please share your project details, and let’s turn your ideas into reality together. We promise a professional and prompt response.

Frequently Asked Questions (FAQ)

Answer:

We offer a comprehensive range of CNC machining services, including CNC milling, turning, drilling, and grinding. We are equipped with advanced 3, 4, and 5-axis CNC machines that can handle a wide variety of machining operations, ensuring precision and efficiency for any project.

Answer:

Our facility is equipped to handle a vast array of materials, including various grades of aluminum, stainless steel, carbon steel, brass, copper, titanium, as well as plastics like ABS, polycarbonate, PEEK, nylon, and many more. We also work with specialty materials such as composites, ceramics, and high-grade alloys, catering to specific industry needs.

Answer:

Quality is our top priority. We have a rigorous quality control process in place, including initial material inspection, in-process monitoring, and final inspection using precision measuring instruments like CMM (Coordinate Measuring Machines). Our facility adheres to strict industry standards to ensure that every part we produce meets our clients' specifications.

Answer:

Yes, our facility is equipped for high-volume production runs without compromising on precision or quality. We utilize automated CNC machines and efficient workflow processes to ensure timely delivery for large-scale orders.

Answer:

Our lead time varies depending on the complexity and volume of the project. However, we are committed to meeting your deadlines and can offer expedited services for urgent requirements. Please contact us with your project details, and we will provide you with an estimated timeline.

Answer:

Absolutely. We specialize in custom CNC machining solutions tailored to your specific needs. Our team of experienced engineers works closely with clients to understand their requirements and deliver custom solutions that meet their unique challenges.

Answer:

We offer competitive pricing without compromising on quality or service. Our advanced technology and efficient processes allow us to provide excellent value to our clients. Plus, with our price match guarantee, you can be assured that you are getting the best deal for the highest quality service.

Answer:

Getting a quote is simple. You can fill out our online quote request form, email us your project details and specifications, or call us directly. Our team will review your requirements and provide you with a detailed quote promptly.