Sheet Metal Fabrication Services

Crafting Precision, Delivering Strength

At RS MFG, we harness advanced technology, masterful craftsmanship, and stringent quality control to meticulously transform raw materials into high-quality, robust components suitable for a broad array of applications.

Why Choose RS MFG for Sheet Metal Fabrication?

Harnessing cutting-edge machinery for precise cutting, bending, joining, and finishing in fabrication.

Expertly handling a diverse range of materials, including stainless steel, aluminum, copper, brass, and more.

Providing tailored fabrication services to perfectly align with your unique project needs and specifications.

Focusing on customer satisfaction, dedicated to excellent service and maintaining clear, continuous communication.

Committing to superior quality and precision, meeting strict standards for exemplary final products.

Offering competitive, transparent pricing, ensuring top-notch quality and precision without overstretching your budget.

Prioritizing timely delivery, understanding the critical importance of adhering to your project timelines.

Featuring a team of skilled fabricators and engineers, collaborating closely with clients for optimal results.

Our Sheet Metal Fabrication Capabilities

Cutting

Laser cutting, plasma cutting, and waterjet cutting for precise and clean cuts.

Bending

Advanced press brakes with a range of capabilities for precise bending and forming.

Joining

Welding, riveting, and adhesive bonding to ensure strong, durable joints.

Finishing

Painting, powder coating, and plating to protect and enhance the appearance of the final product.

Industries We Serve & Case Study

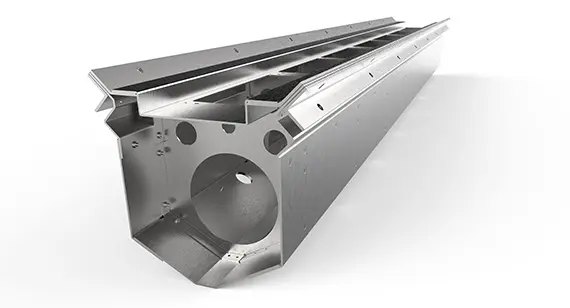

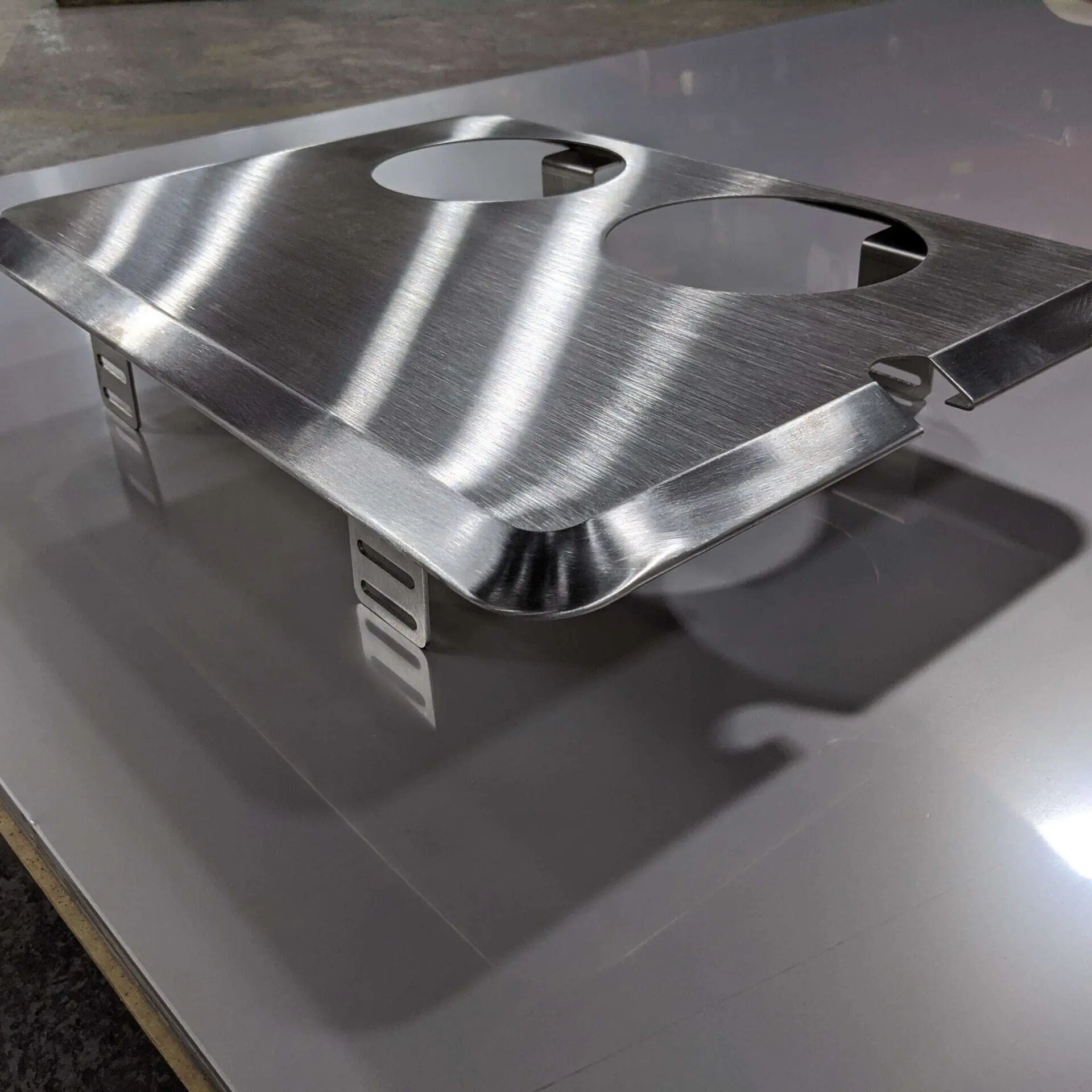

We produced complex, custom automotive components through precision sheet metal fabrication, leveraging advanced techniques for design optimization, precision cutting, and assembly, ensuring superior durability and performance.

We met aerospace industry's stringent quality demands by crafting precision components from high-grade materials, employing advanced fabrication techniques, and adhering to strict testing protocols for unmatched reliability.

Our role in major construction involved fabricating structural components with meticulous precision. Employing robust processes and rigorous quality control, we ensured enduring strength and reliability in infrastructure.

Ready to Get a Sheet Metal Fabrication Quote?

We’re here and eager to offer you high-quality custom services. Tell us about your project needs, and let’s work together to make your vision a reality. We promise you’ll receive our professional and swift response.

Frequently Asked Questions (FAQ)

Answer:

We offer a comprehensive range of sheet metal fabrication services, including cutting (laser, plasma, waterjet), bending (with press brakes), joining (welding, riveting, adhesive bonding), and finishing (painting, powder coating, plating). Our capabilities allow us to handle projects ranging from simple components to complex assemblies.

Answer:

Our facility is equipped to work with a wide variety of materials, including stainless steel, aluminum, copper, brass, and other specialty metals. We carefully select the material based on your project requirements, ensuring durability, functionality, and aesthetic appeal.

Answer:

Absolutely. We specialize in custom fabrication solutions tailored to your specific needs. Our team collaborates with you to understand your project requirements and deliver custom solutions that meet your unique challenges, regardless of the complexity of the design.

Answer:

Quality is integral to our operations. We follow a strict quality control process, which includes rigorous material inspection, precision measurements during fabrication, and thorough checks of the final product. Our adherence to industry standards ensures that every fabricated component meets our high-quality benchmarks.

Answer:

Our lead time varies depending on the complexity and volume of the project. However, we are committed to delivering your project on time without compromising quality. We can provide an estimated timeline once we review your project details.

Answer:

We offer competitive pricing while ensuring the highest quality and service. Our advanced technology and efficient processes allow us to optimize costs and provide excellent value to our clients. We also offer a price match guarantee, ensuring you receive the best price without sacrificing quality.

Answer:

Yes, we provide a range of finishing services, including painting, powder coating, and plating. These finishing services not only enhance the appearance of the final product but also provide additional protection against environmental factors, ensuring longevity and durability.

Answer:

You can easily get a quote by filling out our online request form, emailing us your project specifications, or calling us directly. Our team will review your requirements and provide you with a detailed quote promptly.